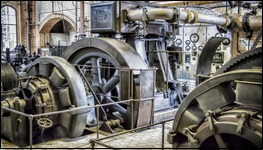

We Power the Grids

To meet the high demands of the power industry, Stein has designed seals that virtually eliminate leakage and shaft rub damage. This has resulted in significant increases in operating efficiency while reducing expensive and time-consuming maintenance requirements.

Stein products are especially effective in meeting the critical requirements for reliability and safety needed for the power industry. To meet the high demands of the power industry, Stein has designed seals that virtually eliminate leakage and shaft rub damage.

Power Generation Seals

Large generators are typically filled with hydrogen to reduce windage losses caused by the generator rotor. While a hydrogen environment makes the generator more efficient, the extreme flammability of hydrogen poses operating and environmental risks to the generator and power plant personnel. To mitigate hydrogen leakage, generators use complex sealing systems around the main shaft that rely on oil pumped into gland type seals at a pressure higher than the generator hydrogen pressure. These gland type seals contain the hydrogen in the generator casing.

Traditional generator hydrogen sealing systems have issues due to large quantities of oil required for sealing, potential oil ingress into the generator casing, i shaft movement during startup, etc. These issues have been solved by Stein Seal® Company’s patented Hydrovent™ and Hydroload™ generator hydrogen seals. These seals offer the following benefits:

a. Significantly reduced oil consumption

b. Significantly reduced oil and hydrogen leakage

c. Sealing during a loss of oil condition

d. Improved seal life, up to 50,000 hours

e. Easy maintenance and replacement as the seals are split and can be replaced directly on the generator shaft

f. Higher tolerance for shaft movement during generator startup

This seal design can be incorporated into any OEM turbine-generator to provide lasting value to the end user. To confirm performance, dynamic tests can be run in Stein Seal® Company’s dynamic test lab.

We welcome the opportunity to discuss your turbine-generator sealing needs, and any other unique sealing issues that you may have. Our over 65 years of experience and 50 patents provides us a long history of solving the most difficult sealing problems.