API 682 Seals

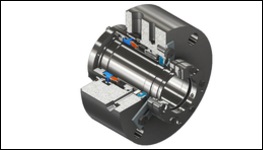

The Stein Seal® Company has developed API (American Petroleum Institute) 682 seals for the oil and gas industry market. Stein Seal has designed, manufactured and tested a Type A & Type C pusher seal, Arrangement 3, dual pressurized cartridge seal for this market.

The Stein Seal ® Company has developed API1 STANDARD 682 seals for the oil and gas industry. Stein Seal ® has designed, manufactured and tested the seals according to the rigorous API Standard 682 test protocols. In general, these are balanced seals with cartridge construction. These seals are classified in to Types, Category, Arrangements and Configurations. The seals are designed and tested to operate continuously for 25,000 hours without need for replacements.

HIGH PERFORMANCE TYPE-A CONTACTING WET API 682 SEALS

The Stein Seal® Company has developed API (American Petroleum Institute) 682 seals for the oil and gas industry market. Stein Seal has designed, manufactured and tested a Type A pusher seal, Arrangement 3, dual pressurized cartridge seal for this market. In an Arrangement 3 design the barrier fluid pressure is kept higher than the seal chamber pressure and is designed to handle and contain hazardous and light hydrocarbon fluids. The process-end face (inner) seal is specially balanced to handle reverse pressures while the atmospheric-end (outer) seal will contain the barrier fluids.

HIGH PERFORMANCE TYPE-C CONTACTING WET API 682 SEALS

The Stein Seal® Company has developed API (American Petroleum Institute) 682 seals for the oil and gas industry market. Stein Seal® has designed, manufactured, and tested a Type C bellows seal, Arrangement 3, dual pressurized cartridge seal for this market. In an Arrangement 3 design the barrier fluid pressure is kept higher than the seal chamber pressure and is designed to handle and contain hazardous and light hydrocarbon fluids. The process-end face (inner) seal is specially balanced to handle reverse pressures while the atmospheric-end (outer) seal will contain the barrier fluids.